For decades, the humble petri dish has been an iconic piece of laboratory hardware, used by researchers to grow all manner of biological samples, from bacteria to brain cells, in different sorts of environments. This simple glassware has also played a starring role in a long line of scientific breakthroughs. The next breakthrough, however, may be a re-imagining of the petri dish itself.

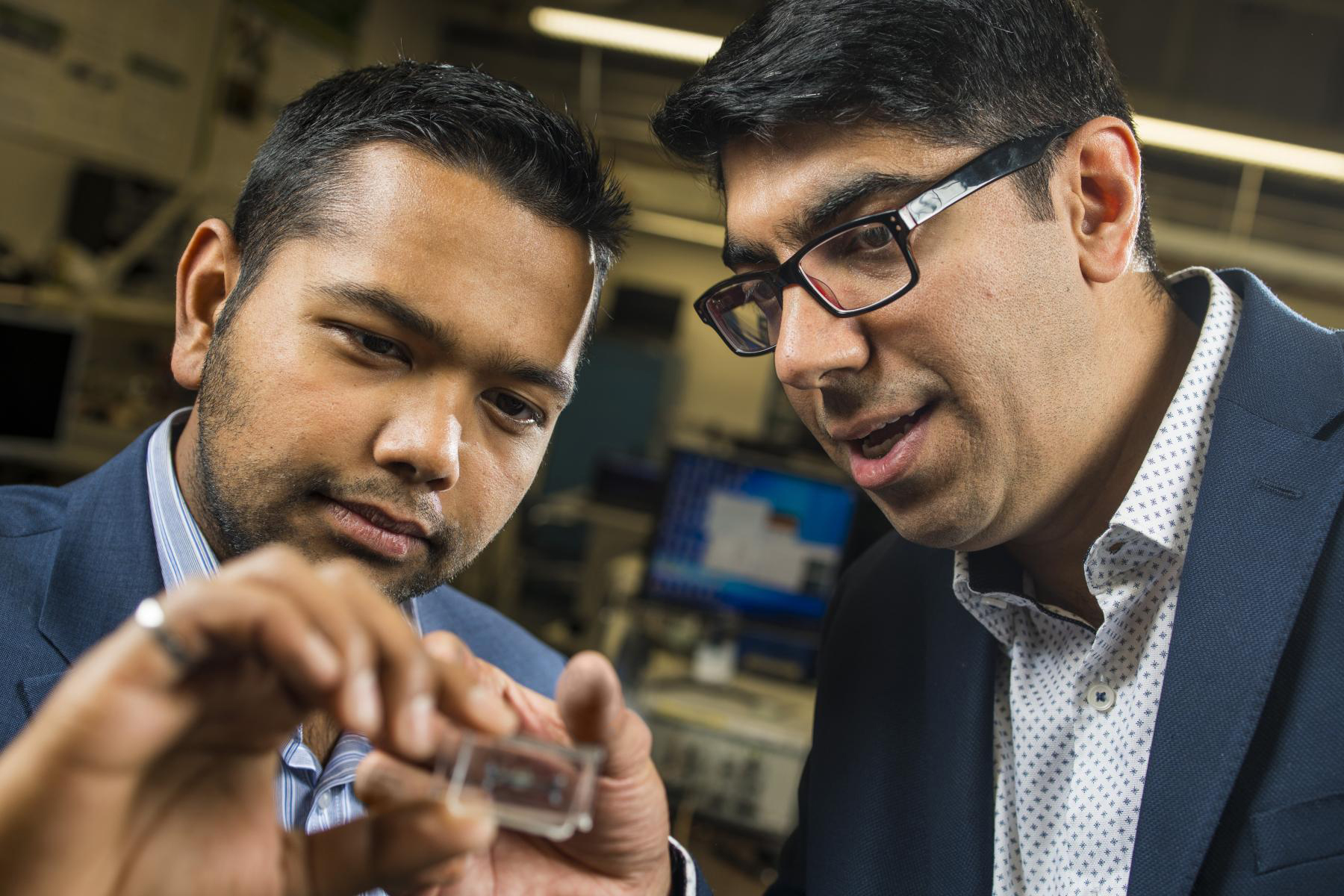

“We are working on the next-generation petri dish,” says Neil Roy Choudhury, CEO of Calgary-based Frontier Fluidics. He and Hamid Sadabadi, who serves as CTO, founded the firm early in 2017 to bring the powerful capabilities of microfluidics design to researchers in the scientific community who might not otherwise have access to its potential.

That potential was evident in the 1990s, when engineers and chemists turned their attention to the finely honed etching tools used by computer chip manufacturers. They discovered that by carving out microscopic channels in solid substrates (such as silicon), they could manage interactions between very tiny amounts of reagents in extreme detail, quickly and easily, introducing what became known as a “lab on a chip”.

Since then, microfluidics have paved the way for compact, self-sufficient analytical systems that can carry out intricate chemical tests, such as checking for pollutants in a lake or river, without the expense and bulk of the traditional laboratory benchtop. These products are substantially changing the way a lot of field work is done, but according to Choudhury, the changes have yet to arrive in many laboratories.

“Unless they happen to be working with people who are developing these systems, a lot of researchers do not have easy access to microfluidics,” he explains, noting that those in the biological sciences could especially benefit from such access. Frontier Fluidics was established to identify those needs and create devices tailored to meet them. “We’re essentially creating a custom service for each lab that we work with,” he says.

Choudhury and Sadabadi became friends while working at an Edmonton firm. Both had graduated from Concordia University, where Choudhury completed his undergraduate degree in aerospace engineering and Sadabadi obtained his PhD while working on microchip-based sensors. The two innovators shared an interest in the development of microfluidics and realized that together they could bring unique expertise to an enterprise intended to tap into the emerging markets for this technology.

Sadabadi notes that CMC Microsystems has been very supportive of the company and their research lab by providing software and financial assistance for chip fabrication. “This was critical to the success of Frontier Fluidics,” he says, noting that he first developed links with CMC during his time at Concordia, where CMC enabled him to gain access to industrial fabrication facilities that might otherwise have been out of reach for an academic investigator.

Such access is also crucial to the aims of Frontier Fluidics, which is attempting to operate on the cutting edge of chip design.

“We have capabilities that allow us to compete with international companies,” he says, including the ability to work with a full range of glass or polymer compounds that are required to manage various biological interactions. “We can create 3D chips with either a single layer or multi-layer that mimic the in vivo environment where cells or bacteria grow. Instead of looking at millions of cells on a petri dish and their interactions amongst themselves, you can study the exclusive behaviour of single cells in a high throughput system.”

Sadabadi says the resulting arrangement anticipates an even more promising technology development: “organ on a chip,” a cell culture device capable of modelling the biochemical behaviour of complex biological systems such as the liver, lungs or heart. While still in its infancy, with many R&D challenges to be overcome, this technology field shows great promise in the study of disease, toxicology, and drug development.

The two entrepreneurs see such specialized products as eventually becoming a prominent part of the company’s business, but in the immediate future they are seeking technological support from CMC as well as funding from federal granting agencies to establish a line of standardized microfluidics chips, which could become as much a part of the laboratory inventory as petri dishes currently are. Such a direction would also provide stable and reliable income to allow for the company’s ongoing growth.

“We are currently developing a generic microfluidics chip that can be used for several applications,” says Sadabadi. “This will help us to become internationally competitive.” The researchers envision a day when petri dishes might be a thing of the past, should their company’s ambitions come to fruition.

Photo: John Ulan/Photo Features

November 2017