Overview

LTCC technology is a general-purpose multi-layer ceramic process used in various areas, namely:

- Medical sensors and electronics

- Automotive electronics

- Satellite electronics and other vehicles in harsh environments

- RF/microwave/mm-wave communications

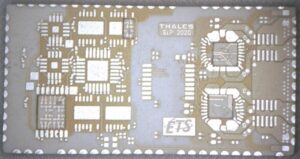

CMC provides access to LTCC prototyping and other related services through the LTCC@ÉTS laboratory, including technical support on the LTCC process and access to the design kit.

Applications

LTCC can be used in a wide range of applications including, but not limited to, the following:

- Ceramic packaging

- Compact lumped components (RLC)

- Low-loss RF, microwave and mm-wave circuits

- Printed and dielectric resonator antennas

- Thermal management through metallized thermal vias

- Ceramic interposers for multi-chip module integration

- High-speed interconnects for wire-bondable or flip-chip assembled components

Related Services

Additional services available at the LTCC@ETS laboratory include:

- Die Mounting and wire bonding, gold balling and flip chip ultrasonic attach

- DRC and engineering support for LTCC design

- X-ray internal structure inspection

- Electrical characterization using network and spectrum analyzers