Even as a child, Neil Sarkar was fascinated by what the naked eye could not see. From award-winning science fair projects to his PhD and postdoctoral research, he has always been looking for ways to see the invisible – and share these discoveries widely. His vision came to life through atomic force microscopy (AFM), and the founding of ICSPI Corp. while a student at the University of Waterloo. The firm continues to grow with new leadership, and game-changing technology and products.

Atomic Force Microscopy

Atomic Force Microscopy (AFM) is a powerful tool used in nanotechnology and material science to examine surfaces at the atomic and molecular levels. Imagine you have a tiny, incredibly sharp needle (probe) at the end of a flexible cantilever. The AFM probe, usually made from silicon or a silicon compound, is no larger than a few nanometers. The small size allows it to interact with individual atoms on a surface. As the needle approaches the surface, atomic forces between the atoms on the needle and the atoms on the surface come into play. These forces cause the cantilever to bend slightly. A laser beam is then directed onto the back of the cantilever, and the deflection of the laser beam is measured.

‘This has been a 10-year journey. CMC supported us the entire way from the initial launch of the company through to commercialization and servicing international clients.’

By analyzing the deflection of the laser beam, scientists can create a detailed map of the sample surface at atomic and sub-atomic scale, allowing researchers to study and understand the structure and properties of materials with incredible precision. AFM is an essential tool for research and quality control in materials science (including semiconductors), molecular engineering, physics, cell biology, health sciences, and more.

Overcoming Challenges

AFM is a powerful technology but presents some challenges that Sarkar and ICSPI wanted to overcome. Traditional atomic force microscope instruments were difficult and time-consuming to operate, largely unchanged since their invention in the 1980s. Their cost and complexity hindered widespread adoption, especially for emerging firms in the booming field of nanoscience. The solution: AFM-on-a-chip technology that was developed over the course of ten years at the University of Waterloo.

Breakthrough: Microscopic Microscopes

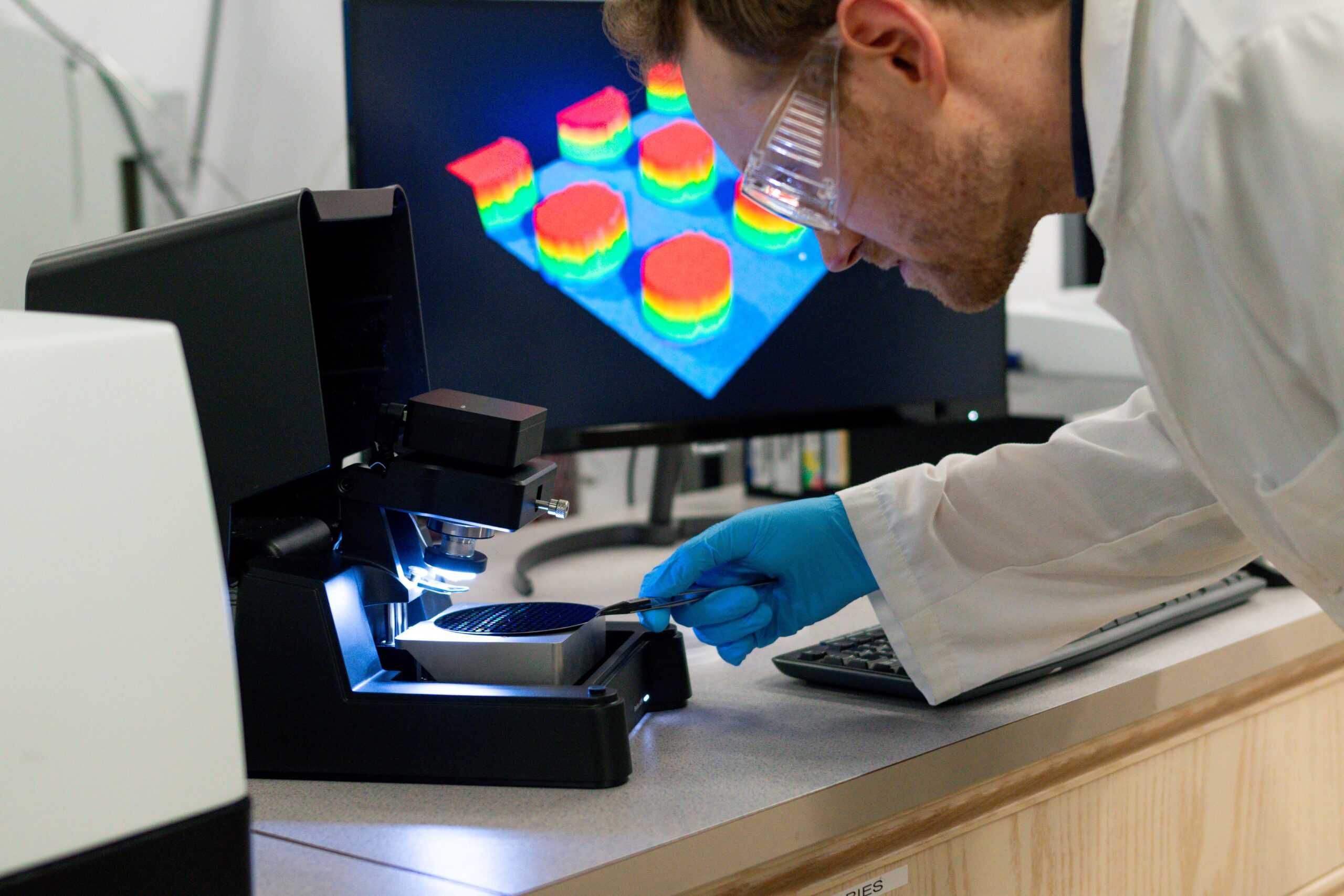

ICSPI integrated many of the sensing and movement components required for an AFM to function on a single, tiny MEMS chip. These “microscopic microscopes,” as Sarkar and partners called them, offer the performance of traditional, dishwasher-sized AFMs but at a fraction of their size and cost. This breakthrough led to the 2017 launch of ICSPI’s nGauge AFM system – currently installed in over 30 countries, for customers including leading universities, research institutes, and firms from startups to Fortune 500 companies.

Introducing: Redux AFM

The firm recently launched its latest AFM platform, the Redux. Powered by more advanced electronics, the Redux features the ease of use and benchtop formfactor of the nGauge, but with increased automation, faster throughput times, and a larger sample platform. “Our goal with the Redux is to make AFM as fast and as intuitive as optical microscopy, so scientists and engineers can focus on advancing scientific discovery and technological progress, instead of spending time getting their instruments to work,” says David Morris, Director of Operations at ICSPI.

CMC has been a partner since Day One

When ICSPI designers and engineers set out to make an AFM-on-a-chip, they were in unexplored territory. They turned to CMC for design support, CAD tools, and fabrication services. “CMC was a huge help for us, especially early on” says Morris. “They provided us with the expertise to perfect our technology and access to fabricate our very first AFM-on-a-chip at some of the world’s best foundries.”

The relationship between CMC continues after over a decade of growth. “This has been a 10-year journey. CMC supported us the entire way from the initial launch of the company through to commercialization and servicing international clients.”

Photo: Courtesy ICSPI

March 2024